2023-01-12

2023-01-12

loading...

loading...

Recently, the China Association of Construction Enterprise Management announced the Decision on the 2022 Science and Technology Award for Engineering Construction. Two technological achievements—Innovative Technology and Practice for Prefabricated Construction of Super High-rise Steel-concrete Structure Buildings of Guangzhou Municipal Engineering Machinery Construction Group, GMC, and Key Technologies and Applications of Tunnel Concrete Durability under Multi-factor Conditions of Guangzhou Institute of Building Science Group—won the second prize of 2022 Science and Technology Progress Award for Engineering Construction.

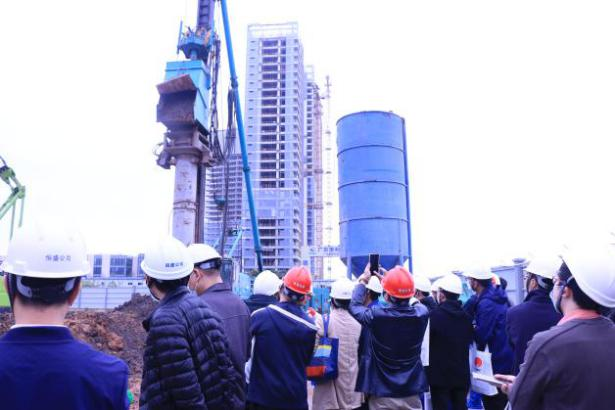

Lower the difficulty of foundation treatment in karst cave areas

The project Innovative Technology and Practice for Prefabricated Construction of Super High-rise Steel-concrete Structure Buildings of Guangzhou Municipal Engineering Machinery Construction Group focused on China Southern Airlines Building. With a height of about 150 meters, the main building is adjacent to Baiyun Park Station of Guangzhou Metro Line 2 and is located in a highly developed area with a karst area rate of 70%, which made it difficult for foundation grouting. Therefore, it’s necessary to reduce the dead weight of the structure to shorten the pile length while meeting the requirements of high-rise buildings for the axial compression ratio and ductility of shear walls.

For this purpose, the project research team took into consideration the actual characteristics of the project and proposed a new prefabricated steel-concrete composite structure system composed of prefabricated concrete-filled steel tube columns, U-shaped steel composite beams, and double-layer steel plate composite shear wall core tubes. The structural system has realized full cladding of the main stress components in high-rise public buildings, thus maximally minimizing the wall thickness, meeting the requirements of high axial compression ratio and high ductility, effectively reducing the dead weight, and significantly relieving the difficulty and cost of foundation treatment in karst cave areas.

Besides, the team has developed the technology for the segmented construction and installation of double-layer steel plate composite shear walls and large-scale internally poured concrete steel box transfer beams, and the technology for the construction of U-shaped steel composite beams and floor decks, which contributed to significant improvement in the prefabricated construction efficiency. In accordance with decoration requirements, the team also offered an integrated decoration plan with a decorative panel system of the floor, interior partition wall, and ceiling wall, and adopted BIM information technology during the whole construction process to ensure the accuracy of construction.

With the help of the achievements, the China Southern Airlines Building project has realized an overall prefabrication rate of more than 90%, which not only effectively improved the construction quality but also fulfilled cost saving and green construction, presenting remarkable economic benefits. The achievements have reached a globally advanced level and have attained a number of national patents, provincial methods, papers, and BIM technology awards.

Present a method of optimizing concrete durability in tunnel engineering

China has now become one of the countries with the largest scale and the highest level of difficulty in tunnel engineering construction across the world. Tunnels are key infrastructures and interregional economic arteries in transportation, so it is critical that tunnels can remain in healthy service for a long time. However, the complex natural environment may make the tunnel concrete structure prone to degradation in durability, having a negative impact on normal service.

Against several key problems in the field of tunnel concrete structure durability, such as “delicate materials, imperfect models, lack of consideration of environmental factors, and difficulty in the prediction of durability and life”, the research team of the project Key Technologies and Applications of Tunnel Concrete Durability under Multi-factor Conditions of Guangzhou Institute of Building Science Group presented the method of optimizing concrete durability in tunnel engineering, developed the rebar rust-expanding cracking model and simplified application model of chloride ion transportation for the concrete cover of tunnel structure, and explained the ion migration behavior of tunnel concrete under high water pressure or stray current environment, thus finally fulfilling the prediction of durability and life of tunnel structure under multi-factor conditions.

The research team has conducted independent research and development and launched a high water pressure environment simulation test device, which can simulate the hydrostatic pressure water environment from 0 to 1.5 MPa and effectively avoid disturbance to the stress state and integrity of concrete during the test. Against the DC corrosion of concrete structures in metro tunnels, the research team also pushed the limits in research and designed a concrete durability test method to simulate AC stray current corrosion, which effectively clarified the ion migration and interaction mechanism in cementitious materials under the action of AC electric field.

The research achievements of the project have been well applied in many tunnel projects such as the Big Hengqin Mt Tunnel in Zhuhai, which effectively extended the service life of the tunnel structure and minimized the operation and maintenance cost of the whole life cycle of the tunnel, thus delivering strong support for the healthy service of the tunnel and advancing the healthy development of key infrastructure construction in transportation.

Source: Guangzhou Municipal Engineering Machinery Construction Group, GMC; Guangzhou Institute of Building Science Group

Edited and released by Lu Chongyou and Long Kun, Party-Masses Work Department of the Group

Released by Zhang Xiaoying, Group Office